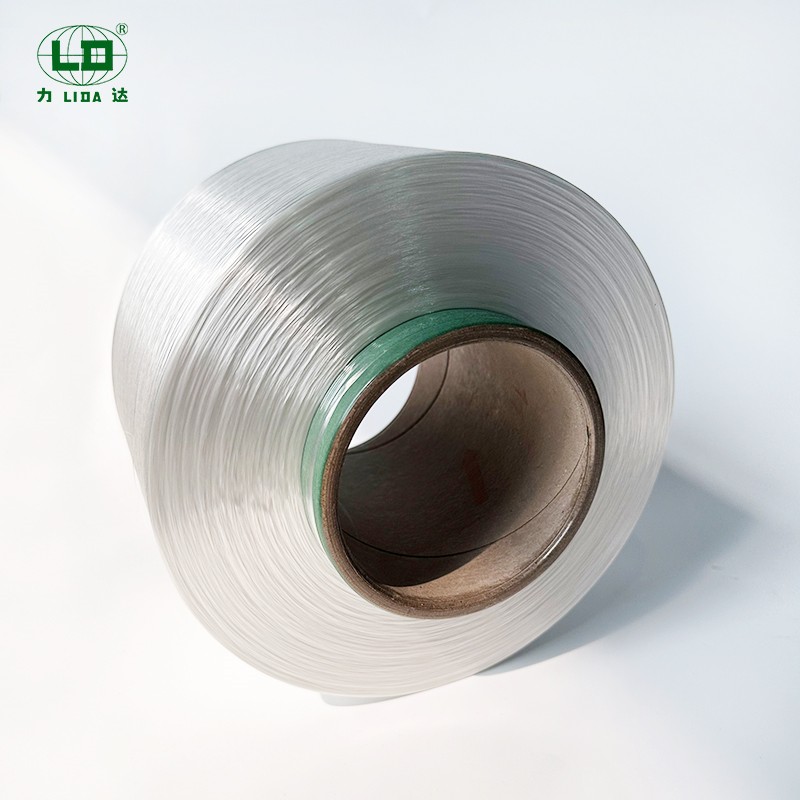

The mechanical strength advantage of polyester industrial yarn comes from the directional arrangement of its molecular chains and the optimized design of its crystal structure. The material is oriented by multi-stage stretching during the melt spinning process, so that the polyester polymer forms a highly ordered axial arrangement, and the accumulation of covalent bond energy significantly improves the tensile strength. The short fibers used in ordinary yarns have random curling during the spinning process, and the intermolecular forces of cellulose or low-oriented synthetic fibers are weak, resulting in uneven stress distribution.

The degree of polymerization of polyester industrial yarn is controlled in a specific range, and the rigid main chain of the benzene ring structure and the polarity of the ester group work together to form an energy barrier to resist deformation. Conventional polyester or natural fibers used in ordinary yarns are prone to molecular chain slippage when external forces are continuously loaded due to their wide molecular weight distribution. Surface modification treatment constructs a nano-scale rough structure on the surface of polyester industrial yarn to enhance the interfacial bonding between the fiber and the matrix material, while ordinary yarns mostly rely on physical twisting to achieve cohesion.

In terms of fatigue resistance, polyester industrial yarn introduces elastic energy storage nodes in the molecular chain segment by controlling the heat setting process of pre-oriented yarn, which has better cyclic load tolerance than the linear viscoelastic response of ordinary yarn.

In terms of chemical tolerance, the hydrolysis rate of the ester bond of polyester industrial yarn in acid-base environment is suppressed by copolymerization modification, and the aromatic ring structure forms an electronic shield against photo-oxidative degradation caused by ultraviolet rays. Ordinary yarns, especially protein natural fibers, have a significantly higher probability of chemical bond breakage under the same environment.